Bmps are described for baffle type and coalescing plate separators.

Grease separator water treatment.

Oil water separators are designed and selected after consideration of oil separation performance parameters and life cycle cost.

The effluent from oil water separators is typically discharged to either a sanitary sewer system or a storm sewer.

Oil water separators highland oil water separators are designed for the removal of free floating oil grease and settleable oily coated solids from oil water mixtures associated with many types of industry.

The name is derived from the fact that such separators are designed according to standards published by the american petroleum.

The european standard en 1825 2 requires that water containing organic fat and oils must be collected in a grease trap 7 1 while water with faecal material black water rain water and water.

The separators can be installed below or above grade to help facilities comply with tough spill and discharge regulations and the ability to produce effluent with.

Each has different oil separation capability and are used in different industries.

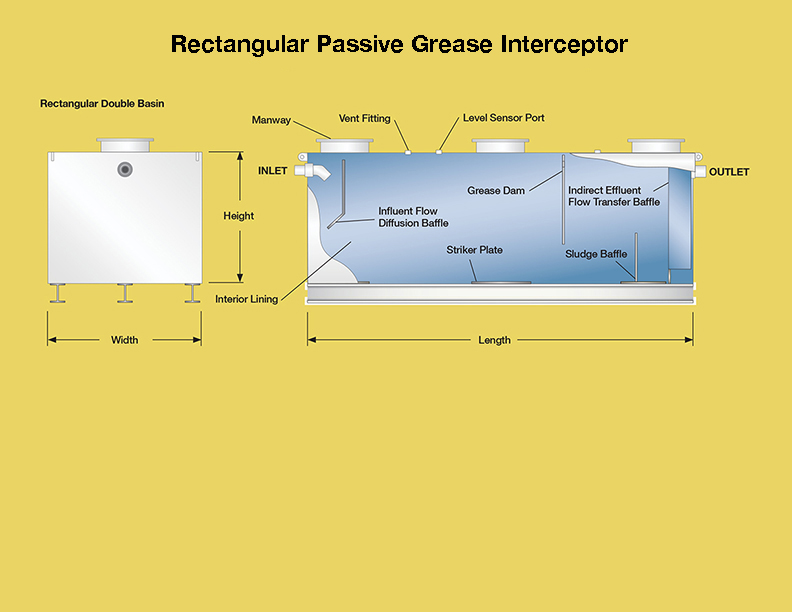

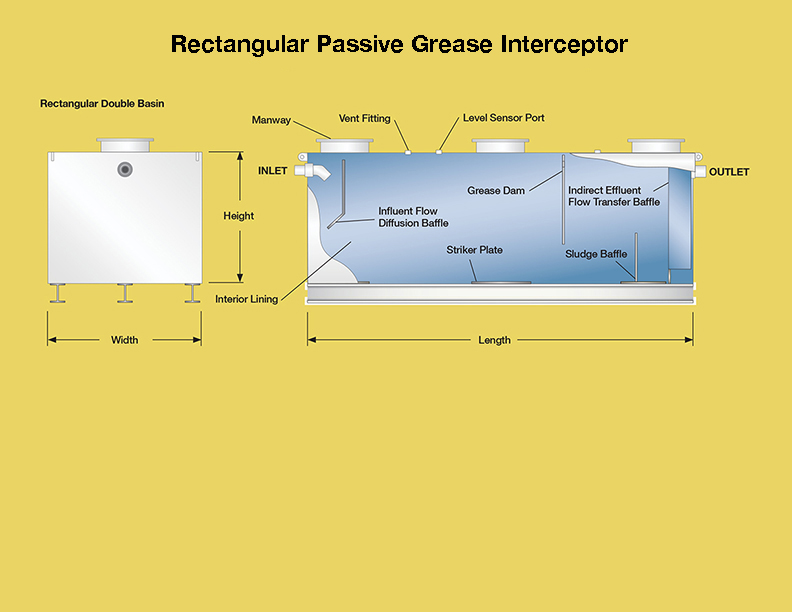

Grease separators are often requested by the public sewerage service and are essential as a pre treatment for small wastewater treatment systems.

Oil water separators oil water separators can efficiently aid in the removal of gasoline diesel fuel crude vegetable and almost any type of oil that is lighter than water.

This chapter provides a discussion of their application and design criteria.

An api oil water separator is a device designed to separate gross amounts of oil and suspended solids from the wastewater effluents of oil refineries petrochemical plants chemical plants natural gas processing plants and other industrial oily water sources.

An oil water separator ows is a piece of equipment used to separate oil and water mixtures into their separate components there are many different types of oil water separator.